30th April 2019

New advances in the 3DPARE project: 3D printing tests done and samples ready for immersion

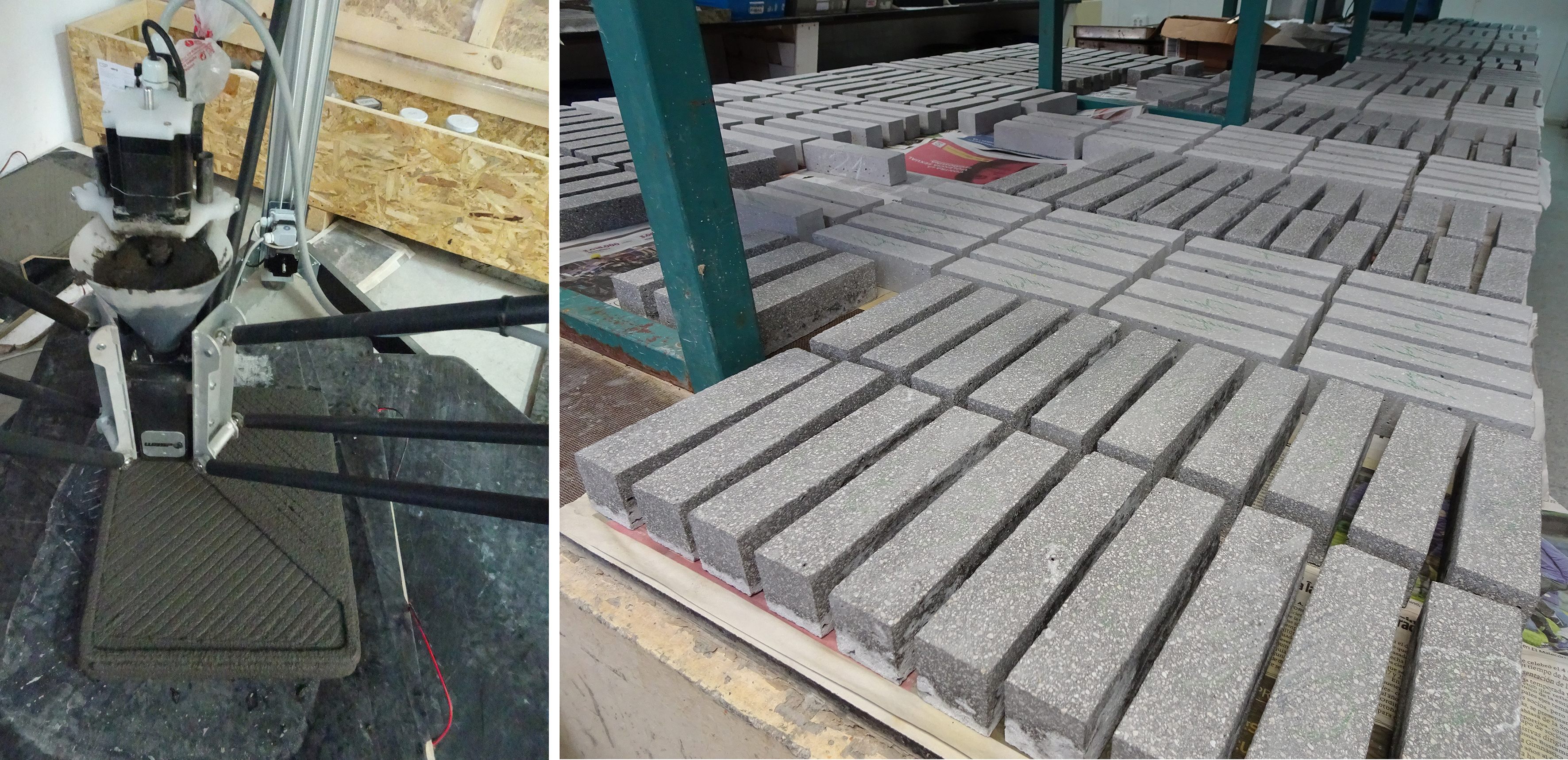

Once the material was characterised, the printing tests were started, which led to modifications in the mixtures to reach an adequate consistency to print; that is to say, soft enough to be extruded but with a consistency able to keep its shape and capable to bear the weight of the top layers of the material to be printed. Another parameter worked was the set time, getting mortars able to keep their initial workability for 1 and 2 hrs. Later, printing was started with different design in other to test the virtues and shortcomings of the equipment and the mortars designed.

Following the planning of the project, three dosages were chosen of geopolymer mortars and 3 of cement mortars. The parameters chosen for this selection were: life cycle analysis, ease to be printed, mechanical resistance and costs.

With the materials selected, slabs were printed, from which specimens were cut, with the purpose to be submerged in different continental platform settings, corresponding to the locations of the different partners of the project (United Kingdom, France, Portugal and Spain).

return

return